Solutions

Contact Us

National 24-hour Service Hotline:400-180-6068

Headquarters Address: No. 999 Ping'an Middle Road, Changqing District, Jinan City

Headquarters Phone:86-531-58755082

Company Email:sale@haozhongauto.com

Headquarters Website:www.jnhaozhong.com

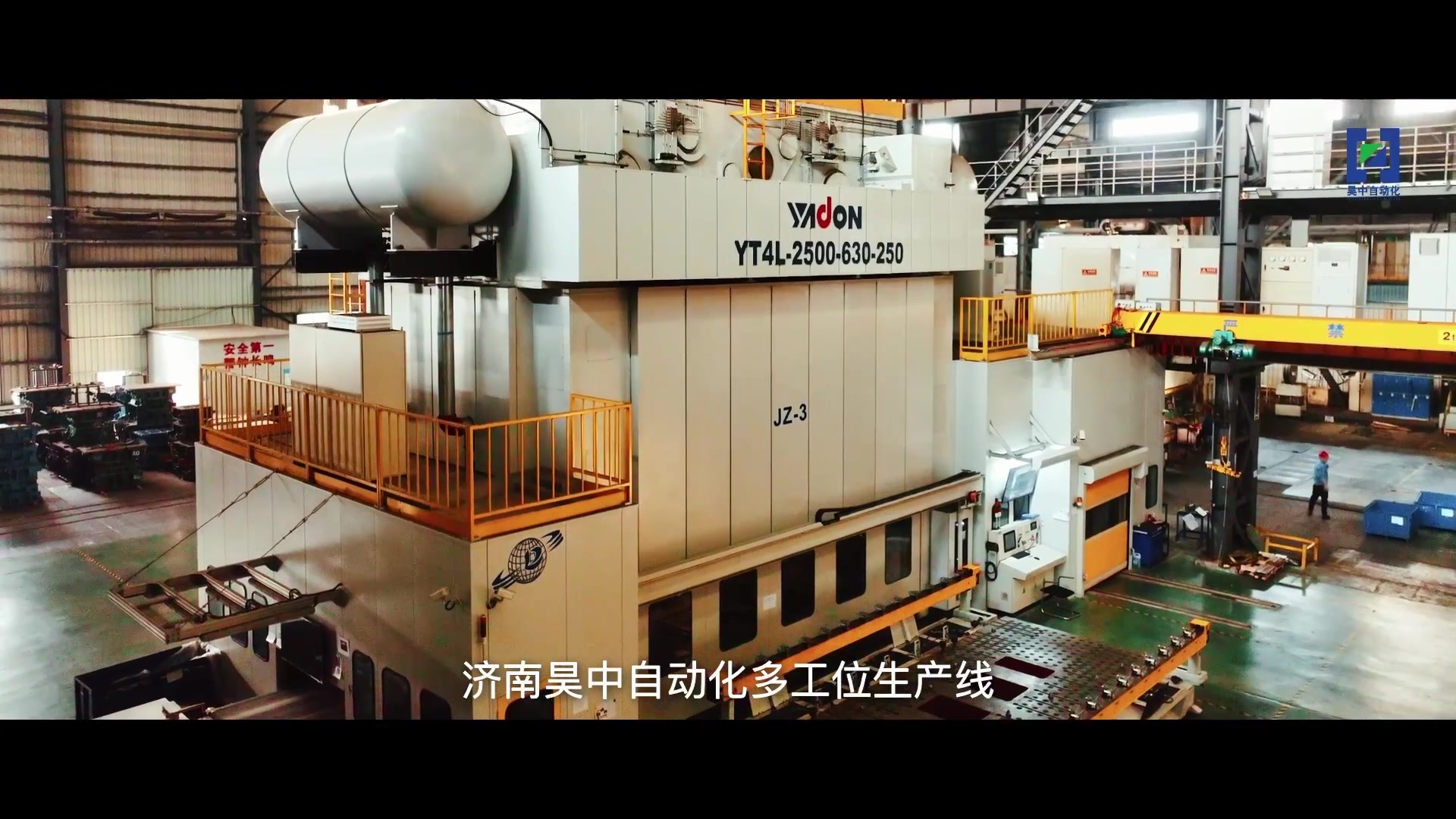

Multi-station stamping automation line

The positioning of the transfer automation system is based on a Cartesian coordinate system. The three actions of clamping/releasing, lifting/lowering, and feeding/reversing are all implemented by linear drive modules. It uses a pneumatic quick-change device, driven by a servo motor, with fast step response and small repeat positioning error. The FOL depalletizer consists of a loading trolley, magnetic fan, depalletizer, conveyor, and centering mechanism. The depalletizer is controlled by two-axis servo motors, with the X-axis moving horizontally and the Z-axis moving vertically. The universal tooling is equipped with dual blank detection functions. After the blank is in place, the conveyor stops, the corresponding servo push rod positions the blank, the feeder picks up the part, and the push rod resets. In the middle of the production line is a three-axis feeder; the dual-arm servo feeding system transfers the blank from the loading station/first station to the next station of the mold. At the EOL, the part is moved by a crossbar to the last operation and placed on the exit conveyor. Then manual inspection and packaging of parts are performed.

Detailed Description

| Introduction: The positioning of the transfer automation system is based on a Cartesian coordinate system. The three actions of clamping/releasing, lifting/lowering, and feeding/reversing are all realized by linear drive modules. It uses a pneumatic quick-change device, servo motor drive, with fast step response and small repeat positioning error. The depalletizer consists of a loading trolley, magnetic fan, depalletizer, conveyor, and centering mechanism. The depalletizer is controlled by two-axis servo motors, with horizontal movement on the X-axis and vertical movement on the Z-axis. The universal tooling is equipped with dual blank detection functions. After the blank is in place, the conveyor stops, the corresponding servo push rod positions the blank, the feeder picks up the part, and the push rod resets. In the middle of the production line is a three-axis feeder. The dual-arm servo feeding system transfers the blank from the unloading station/first station to the next station of the mold. The part moves via a crossbar to the last operation and is placed on the outlet conveyor. Then manual inspection and packaging of parts or online inspection and automatic boxing are performed. Main Customers: Korea Lotte TSA multi-station project, Zhejiang Hailian Jinhui Auto Parts Co., Ltd. 1000-ton multi-station automation system, Changzhou Zhongxin United Auto Machinery Manufacturing Co., Ltd. 2500-ton multi-station automation system, Yisheng Dongmo Monterey 2500-ton multi-station automation system, Wuhu Ruihu Haobo Mold Co., Ltd. 2500-ton multi-station automation system, Chuzhou Dashi Auto Parts Co., Ltd. 1250-ton multi-station automation system, Kunshan Daya Auto Parts Co., Ltd. 2500-ton multi-station automation system |

|

Product Inquiry Message

Please fill in your contact information and requirements, and we will arrange for professional service personnel to contact you!