Solutions

Contact Us

National 24-hour Service Hotline:400-180-6068

Headquarters Address: No. 999 Ping'an Middle Road, Changqing District, Jinan City

Headquarters Phone:86-531-58755082

Company Email:sale@haozhongauto.com

Headquarters Website:www.jnhaozhong.com

Online Quality Inspection

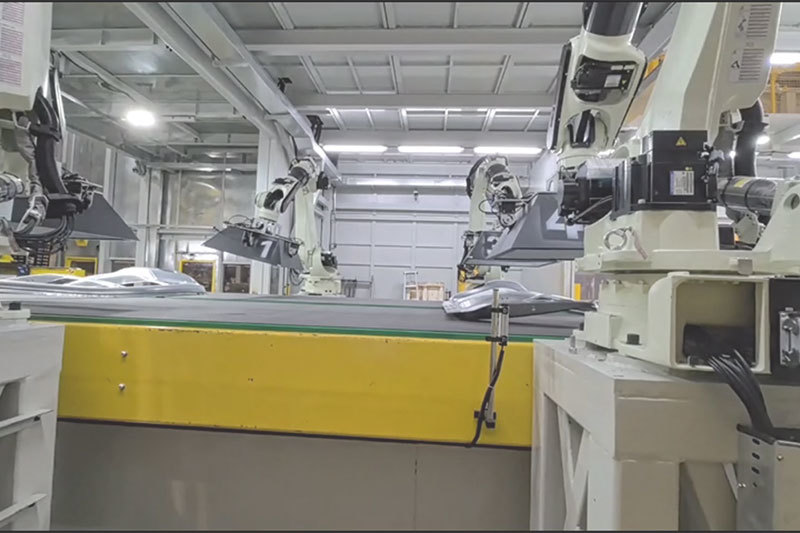

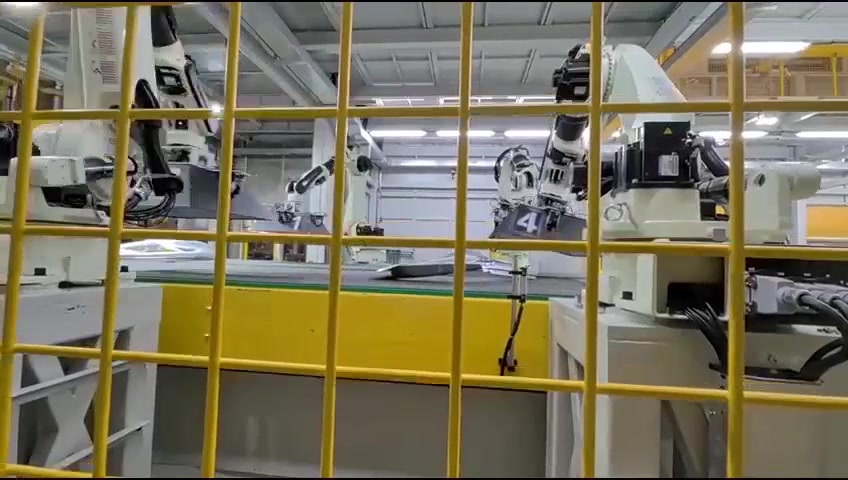

The online quality inspection system for automotive sheet metal stamping parts automatically retrieves the visual inspection recipe based on the stamping workpiece model. Utilizing advanced robotic vision technology, it integrates deep learning algorithms and image processing techniques to simulate the human visual system, conducting comprehensive and high-precision inspections of stamped sheet metal parts. This system replaces manual quality checks, enhancing inspection reliability and stability, and effectively reducing the probability of defective products being released.

Detailed Description

| The online quality inspection system for automotive sheet metal stamping parts automatically retrieves visual inspection recipes based on the stamping workpiece model. Utilizing advanced robotic vision technology, integrating deep learning algorithms and image processing techniques, it simulates the human visual system to perform comprehensive and high-precision inspections of stamped sheet metal parts. This replaces manual quality checks, improves inspection reliability and stability, and effectively reduces the probability of defective products being released. Additionally, periodic manual sampling inspections are equipped to effectively prevent large-scale defective outflows. Defect types detected: Capable of accurately identifying various common defects in formed sheet metal parts, such as pitting, dents, deformation, excessive or insufficient holes, cracking, wrinkling, and other defects. Inspection data management: Automatically records monitoring data and generates detailed quality reports, providing strong data support for quality traceability and process optimization in the acoustic field process. |

|

Product Inquiry Message

Please fill in your contact information and requirements, and we will arrange for professional service personnel to contact you!