Solutions

Contact Us

National 24-hour Service Hotline:400-180-6068

Headquarters Address: No. 999 Ping'an Middle Road, Changqing District, Jinan City

Headquarters Phone:86-531-58755082

Company Email:sale@haozhongauto.com

Headquarters Website:www.jnhaozhong.com

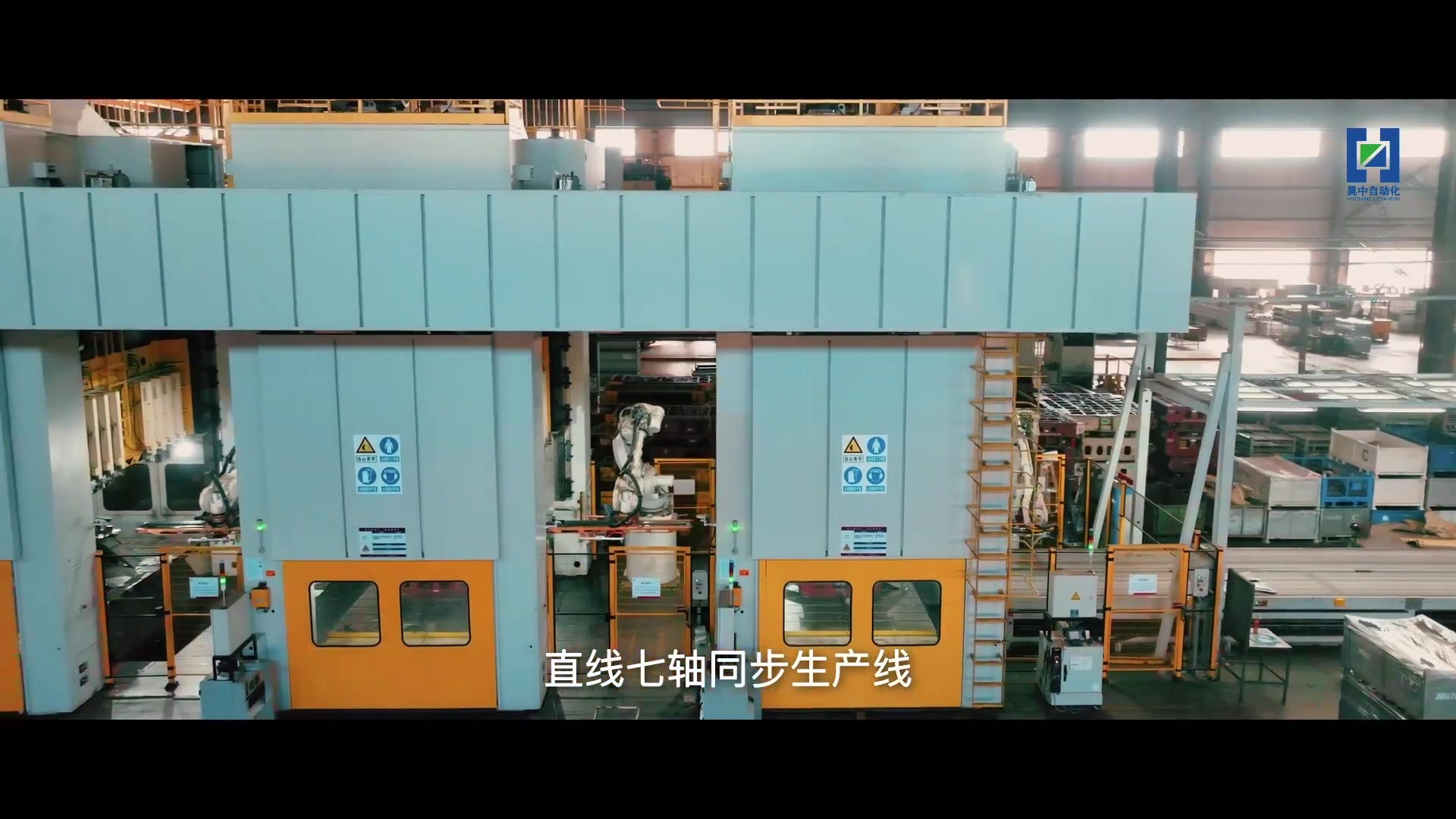

Straight line seven-axis robot continuous line

An external translation speed multiplier axis mechanism is added to the flange of the robot's sixth axis, enabling the workpiece to translate between presses in the front and rear processes. This avoids the previous issues caused by 180° rotation of the workpiece, such as complex trajectories and poor stability, and also greatly improves production rhythm. Simplifying the robot's handling trajectory not only improves production efficiency but also saves space (the press spacing for large cover stamping production lines is generally between 6.2 and 6.3 meters). The linear 7-axis has the characteristics of being lightweight and having high rigidity, which reduces inertia and increases handling speed. Additionally, its compact structure and high load capacity make it suitable for efficient transmission of workpieces with large side dimensions.

Detailed Description

| Introduction: An external translation speed-increasing axis mechanism, the seventh axis, is added to the flange of the robot's sixth axis to achieve the translation of the workpiece between presses in the front and rear processes. This avoids the previous issues caused by 180° rotation of the workpiece, such as complex trajectories and poor stability, and also greatly improves production rhythm, reaching speeds of over 12 SPM. Simplifying the robot's handling trajectory not only improves production efficiency but also saves space (the press spacing for large cover stamping production lines is generally between 6.2 and 6.3 meters). The linear seventh axis features light weight and high rigidity, which reduces inertia and increases handling speed. It also has a compact structure and high load capacity, meeting the efficient handling needs of large-sized workpieces such as side panels. Our company matches various specifications of the seventh axis according to different customer production requirements to minimize investment and operating costs. Combined with the linear seventh axis, our company has independently developed a continuous operation mode for the entire line, where the press does not stop at the top dead center during production line operation, maintaining continuous operation. Compared to the traditional intermittent mode, this effectively increases the cycle rate, saves more than 20% energy, significantly reduces wear on the press clutch and brake, and greatly lowers impact damage to molds. This reduces maintenance costs for equipment and molds substantially, bringing great benefits to customers. Our company is an industry leader in this field with dozens of successful application cases. |

|

Product Inquiry Message

Please fill in your contact information and requirements, and we will arrange for professional service personnel to contact you!