Jinan Haozhong Automation Co., Ltd.

Jinan Haozhong Automation Co., Ltd. was established in May 2011. It is a national high-tech enterprise specializing in the research, development, manufacturing, maintenance, and transformation of stamping automation production lines and CNC machine tools, committed to creating China's leading brand of independently developed high-speed flexible manipulators. The company is headquartered in Changqing District, Jinan, and has successively established branches in Guangzhou, Kunshan, Huzhou, and Chongqing to better serve customers and upgrade industries. The company's new factory was put into use in June 2023, covering more than 13,600 square meters, becoming a first-class domestic base for the research and development and manufacturing of automation equipment.

The company has developed rapidly in recent years and has passed the ISO9001 quality management system certification. It has been recognized as a high-tech enterprise in Shandong Province, a "Specialized, Refined, Distinctive and Innovative" SME in Shandong Province, a "Gazelle Enterprise" in Shandong Province, and a "Specialized, Refined, Distinctive and Innovative" SME in Jinan City. The company's "4000T Robot Automation Equipment," "Multi-station Manipulator," and "High-speed High-flexibility Stamping Robot" have all passed scientific and technological achievement appraisals and reached a domestic leading level. The "6500-ton High-speed High-flexibility Stamping Robot Automation System" has passed new product appraisal. Among them, the "4000T Robot Automation Equipment" and "6500-ton High-speed High-flexibility Stamping Robot Automation System" products have been listed as the first sets of technical equipment and key core components in Jinan City. The "1000T Robot High-speed Automation System" and "Hot Forming Automation System" have successfully passed the acceptance of the Zhong District Science and Technology Plan Project; the "4000T Automation Equipment" project has passed the acceptance of the Jinan City Golden Seed Enterprise Key Product Improvement Plan. The successful implementation of these projects has strongly promoted the development and progress of domestic stamping robot automation technology, filled some technical gaps in China, facilitated industrial structural adjustment and optimization upgrades, driven the development of many related industries, increased tax revenue while leveraging its own advantages, promoted economic structural adjustment, achieved leapfrog economic development, expanded the employment group, increased job positions and workers' income, and made great contributions to improving people's livelihood. In addition, the company has successfully achieved the goal of "going global," having successfully exported to Mexico, Indonesia, and other places, with multiple overseas projects under negotiation, rapidly moving towards internationalization.

Solutions

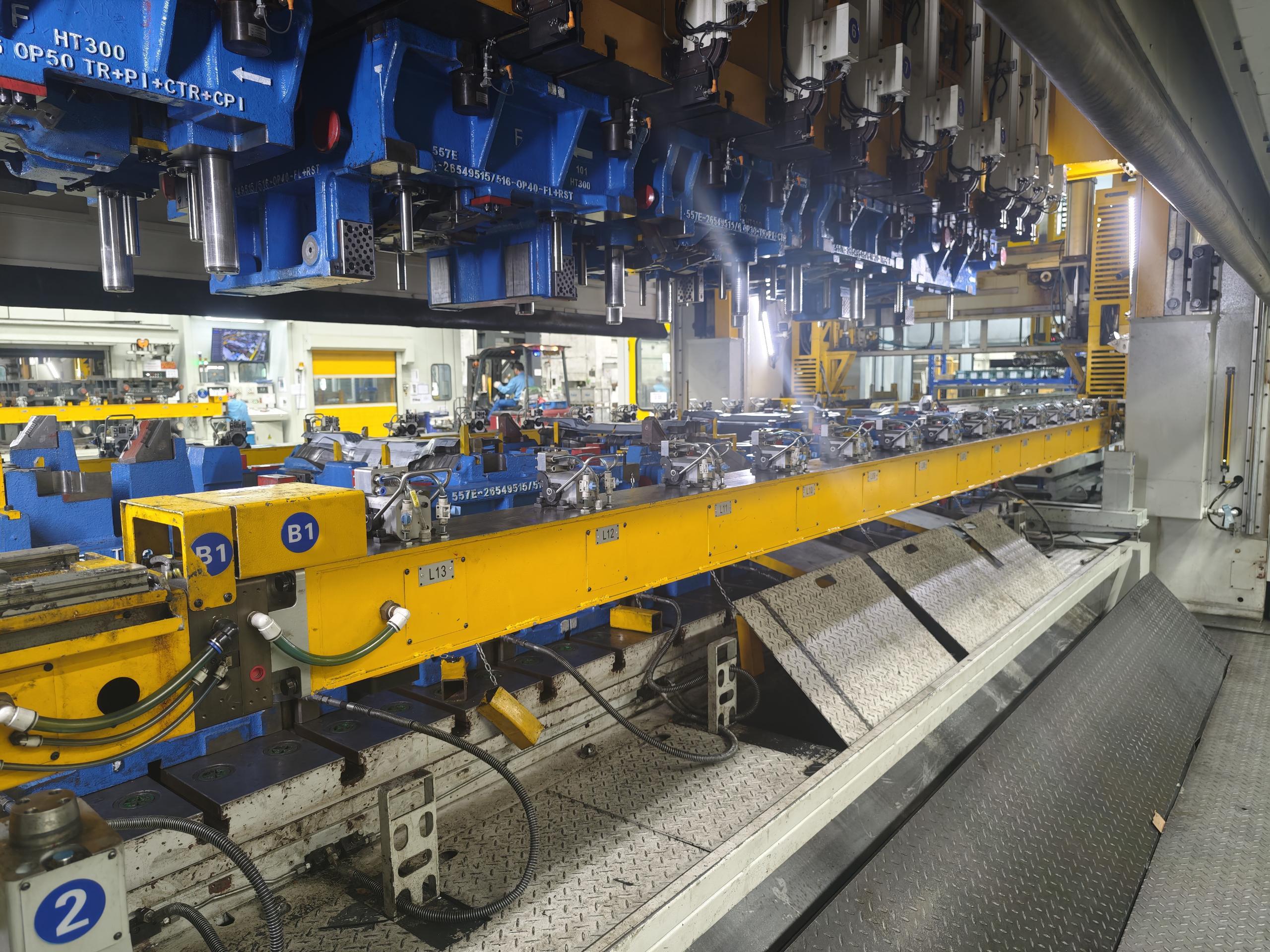

With the rapid development of automotive stamping automation production lines, the high-speed flexibility and stability of material transfer between presses is very critical.

To address this issue, our company formed a R&D team to independently develop, design, and produce the second-generation single-arm manipulator - HSR.

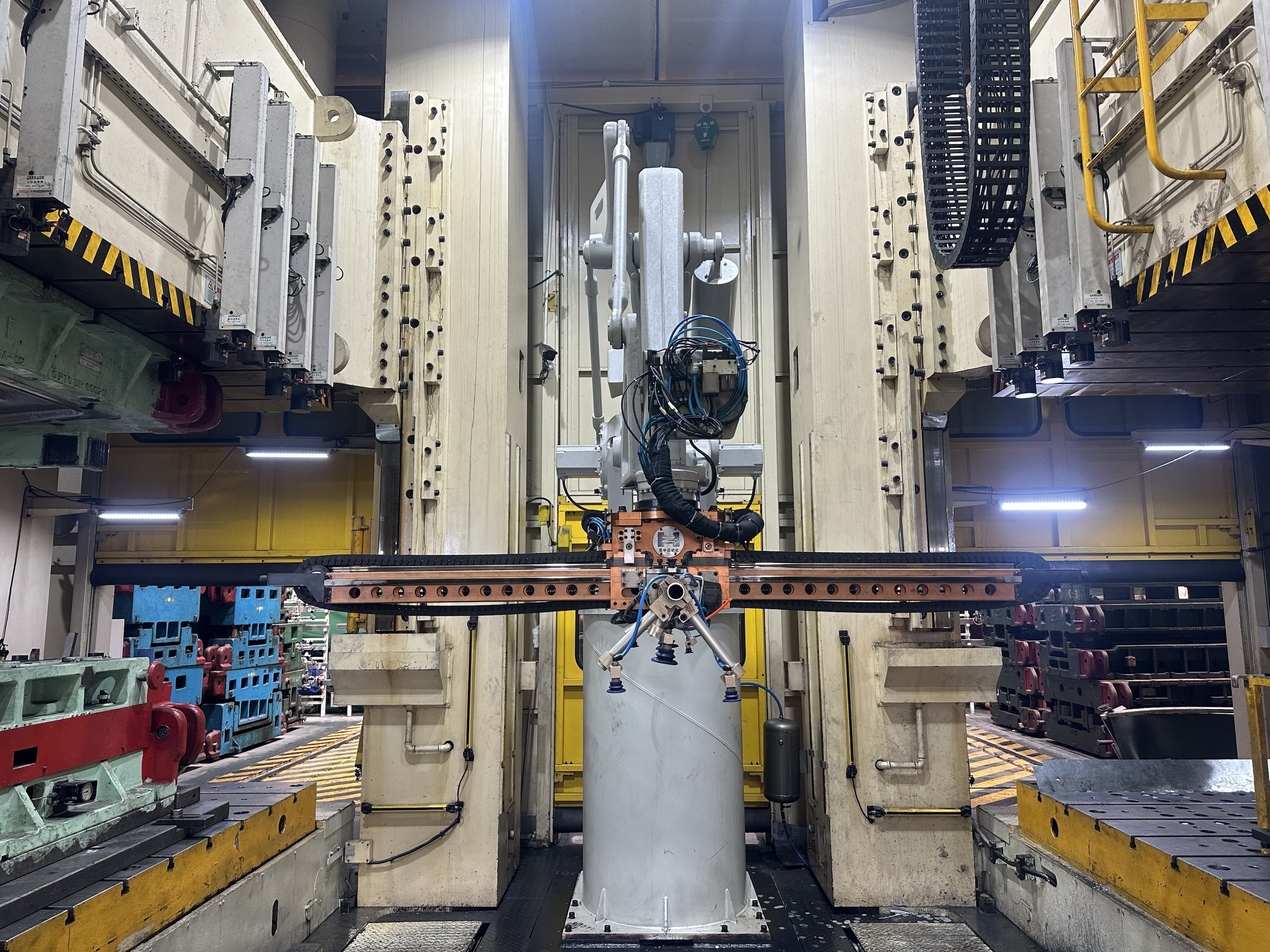

This six-axis linkage high-speed high-flexibility manipulator combines our independently developed multi-axis linkage control system and, together with professors from Tsinghua University, optimizes the optimal trajectory curve through dynamic analysis to ensure the manipulator can quickly, smoothly, and accurately complete the specified motion curve, meeting the production needs of high-speed stamping automation lines.

An external translation speed axis mechanism is added to the flange of the robot's sixth axis to achieve the translation of the workpiece between the presses in the front and rear processes, avoiding the previous problems of complex trajectories and poor stability caused by 180° rotation of the workpiece, while also greatly improving production rhythm.

Simplifying the robot's handling trajectory not only improves production efficiency but also saves space (the press spacing for large cover stamping production lines is generally between 6.2 and 6.3 meters).

The linear 7-axis has the characteristics of light weight and high rigidity, which reduces inertia and increases handling speed. It also has a compact structure and large load capacity, suitable for efficient transmission of workpieces with large side dimensions.

In industries such as automotive and home appliances, sheet metal parts are completed by stamping, and many complex-shaped parts require multiple stamping operations. In traditional industrial robot production lines, when the robot takes the stamped part from the previous press and transfers it to the next press, the stamped part rotates 180° horizontally during this process. If rotation of the sheet metal is not allowed, the transfer of the sheet metal between process steps cannot be realized.

Our company's R&D team developed a rotary seven-axis robot that solves the problem of transferring sheet metal between processes when rotation of the sheet metal is not allowed.

With the diversification of passenger car appearances, the trend of small batch multi-model and even personalized customization is rising, leading to diversity in passenger car cover parts, which requires posture adjustment of stamped parts during stamping processes and demands handling robots to have posture adjustment functions.

Our company's R&D team developed a high-speed flexible stamping handling robot with 7 servo axes, including three translation axes, one speed multiplication axis, and three rotation axes, which balances high-speed handling and flexible posture adjustment functions well, and can adapt to various complex molds.

High flexibility: Six-axis robots have multiple degrees of freedom and can flexibly perform complex trajectory actions (such as workpiece flipping and multi-angle picking and placing), adapting to different molds and product changes. Production rhythm and process paths can be quickly adjusted through programming to meet the needs of mixed production of multiple varieties.

High precision and stability: Handling repeat positioning accuracy can reach ±2mm, ensuring consistency of stamped parts and reducing scrap rate.

Efficient continuous production: Fully automated seamless connection of the entire process, production rhythm can reach 6-9.5 cycles/minute (depending on workpiece complexity). 24-hour continuous operation greatly improves equipment utilization (OEE).

The positioning of the transfer automation system is Cartesian coordinate system, and the three actions of clamping/releasing, lifting/lowering, feeding/reversing are all realized by linear drive modules. Pneumatic quick-change devices are used, driven by servo motors, with fast step response and small repeat positioning error.

The FOL depalletizer consists of a loading trolley, magnetic fan, depalletizer, conveyor, and centering mechanism. The depalletizer is controlled by 2-axis servo motors, with X-axis horizontal movement and Z-axis vertical movement.

The dual-arm feeder is a typical X, Y, Z axis structure, with two working modes: Transfer and Feeder. It can cyclically complete actions such as clamping, lifting, feeding, lowering, releasing, and returning, achieving rapid handling of sheet metal.

The transfer method is suitable for short stamping strokes, large column spacing, and narrow molds. It is suitable for handling long and thin sheet metal. The robot's X-axis and the end picking gripper can stay inside the stamping machine without interfering with each other, occupying less stamping time, which helps shorten the overall line cycle time.

Can achieve independent automatic boxing of two pieces below 16 SPM;

Can meet different forms of inner and outer panel boxing requirements such as hanging, spaced hanging, stacking, and spaced stacking;

Can realize independent boxing of defective products based on instructions from quality inspectors or automatic visual inspection system information, or manual collection at the end of the release line;

Can automatically complete end gripper replacement during the entire line mold change process;

Material box turnover can be carried out by AGV transfer or forklift transfer.

Stamping automation relocation service is provided to meet enterprise needs due to factory relocation, capacity layout adjustment, etc., offering professional relocation of presses and automation equipment. From preliminary equipment evaluation and plan formulation to equipment disassembly, transportation, installation, and commissioning, the entire process is carefully operated to ensure safe and efficient transfer of equipment to the new site and rapid production resumption.

Upgrade and transformation services focus on using advanced technology to improve the automation level of stamping production. By optimizing key links such as existing equipment control systems, loading and unloading processes, automated handling equipment, and one-key mold change, efficient, precise, and intelligent stamping production is achieved, comprehensively improving production efficiency and product quality.

The online quality inspection system for automotive sheet metal stamping parts automatically retrieves visual inspection recipes based on the stamping workpiece model. Using advanced robot vision technology combined with deep learning algorithms and image processing technology, it simulates the human visual system to perform comprehensive and high-precision inspection of stamped sheet metal parts, replacing manual inspection, improving inspection reliability and stability, and effectively reducing the probability of defective products flowing out.

Types of defects detected: Can accurately identify various common defects of formed sheet metal parts, such as dents and bumps, compression scratches, deformation, cracking, wrinkling, porosity, and missing holes.

Cases

Thermoforming production line

Jiangsu

Thermoforming production line

Jiangsu

Multi-station production line

Jiangsu

Five-sequence automatic framing

End-of-line automatic packing

JIlin

Series automation line, 13 SPM

Single-arm high-speed line

Jiangsu

Linear seven-axis intermittent line

Guangdong

2000T seven-axis automation line project, 11 SPM

Linear seven-axis continuous line

JIlin

Straight seven-axis continuous line Beat 12 SPM

Linear seven-axis continuous line

Guangdong

Products

The depalletizing unit can pick up sheet metal one by one from the material stack and convey it to the production line. Our company's depalletizing unit features stable production, high efficiency, and wide adaptability, and can provide the best depalletizing solutions according to customer production line characteristics.

With the widespread use of aluminum alloy materials for automotive outer cover parts, dry cleaning machines are suitable for steel and aluminum plates, especially dry cleaning machines for aluminum plates are increasingly chosen by customers. Dry sheet metal cleaning machines, with advantages of high efficiency, environmental protection, and low maintenance cost, are gradually becoming important cleaning equipment in modern industrial production, especially suitable for stamping production lines with high cleaning quality requirements.

Used for uniformly applying deep drawing oil on the upper and lower surfaces of ordinary steel plates and galvanized steel plates. According to the set mode, both the upper and lower surfaces of the blank can be sprayed with deep drawing oil. The amount of spraying can be adjusted as needed. The oiling machine can be equipped with a walking system and AC variable frequency drive according to the site conditions, walking along laid rails, enabling online and offline functions. Entry and exit are equipped with detection devices to achieve full line interlocking.

The belt conveyor is a widely used material handling equipment in industrial production. It achieves horizontal, inclined, or vertical transportation of materials through the continuous movement of the conveyor belt. It features a simple structure, reliable operation, and easy maintenance, making it an indispensable important equipment in modern industrial production.

The head-end belt conveyor is an important part of the stamping automation production line, responsible for automatically conveying the separated sheet metal to the feeding position of the stamping press. This equipment ensures the continuity and stability of the production line through an efficient and precise conveying system, improving production efficiency, reducing manual intervention, and lowering production costs.

Partners

The company mainly serves top domestic and international automobile manufacturers and their suppliers, including SAIC General Motors (Shanghai Base, Shenyang Base, Yantai Base, Wuhan Base), GAC Group (GAC Aion, GAC Trumpchi), BYD Auto, Changan Automobile, SAIC Maxus, SAIC Hongyan, Great Wall Motors, BAIC Motor, Seres, Chery Automobile, Leapmotor, and other OEMs, as well as many mainstream domestic and international automotive parts suppliers such as Duoli Auto, Bojun Auto, Zhongtai Auto, Wuxiu Auto, Changrui Auto, Yingli Auto, Ruihu Mould, Korea Lotte, Japan Marushun, Japan Topre, and other well-known enterprises. The company also cooperates with many domestic and foreign press machine companies, such as Schuler Germany, Yangzhou Forging, Hefei Forging, Tianjin Forging, Dis Hydraulic, etc., successfully exporting products to overseas markets and continuously expanding market share.